Introducing the Ins And Outs of Fasteners and Machining Procedures for Ideal Performance

In the world of design and manufacturing, the selection of bolts and the ins and outs of machining processes play a pivotal duty in figuring out the supreme performance and longevity of a product. From the seemingly uncomplicated task of choosing the ideal sort of fastener to the facility accuracy machining methods employed, every action in this process needs meticulous focus to detail. As we get started on this exploration right into the world of bolts and machining, we will discover the subtle yet essential elements that can considerably influence the performance and high quality of the end product, clarifying the frequently forgotten elements that can make all the distinction in achieving ideal efficiency.

Relevance of Correct Bolt Choice

Choosing the suitable fasteners is crucial in ensuring the architectural stability and durability of any mechanical assembly. Bolts play an essential function in holding components with each other firmly, with the ideal choice contributing dramatically to the general performance and dependability of the assembly. When picking fasteners, factors such as product compatibility, environmental conditions, load-bearing ability, and simplicity of installation have to be very carefully thought about to guarantee optimum performance.

Improper bolt selection can bring about a variety of issues, consisting of loosening, deterioration, and even architectural failure. Making use of bolts that are not suited to the details demands of the setting up can jeopardize its capability and position safety dangers. Developers and designers should diligently examine the application needs and pick fasteners that meet or surpass the necessary requirements and specifications.

In addition, the right fastener option process involves examining the joint layout, expected loads, resonance levels, and prospective thermal expansion or tightening to ensure that the picked fasteners can hold up against the operating conditions efficiently. By focusing on appropriate bolt selection, producers can improve the top quality, sturdiness, and efficiency of their mechanical settings up.

Kinds and Characteristics of Fasteners

A necessary facet of mechanical settings up exists in recognizing the varied types and distinct qualities of fasteners utilized in numerous commercial applications. Fasteners are critical parts that hold frameworks with each other, making sure security and performance.

Screws are threaded bolts that are generally made use of to sign up with 2 or even more parts with each other. Screws resemble screws but are generally utilized with a nut to produce a protected joint. Nuts are internally threaded bolts that mate with screws to hold elements together. Washers are slim plates that disperse the tons of a fastener, preventing damage to the material being fastened. Rivets are permanent bolts that are hammered or pressed right into area. Pins are utilized for positioning or to secure parts momentarily.

Understanding the qualities of each sort of fastener is necessary for picking the right one for a particular application, ensuring optimal performance and reliability of the mechanical assembly. Fasteners and Machining.

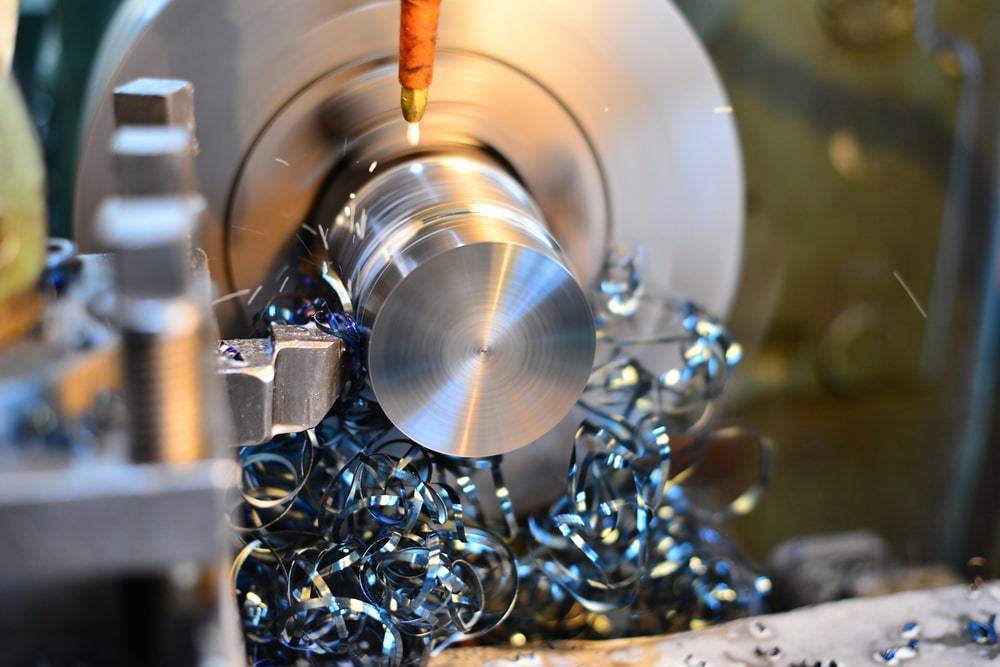

Accuracy Machining Strategies for Efficiency

The detailed layout needs of different fasteners necessitate using accuracy machining strategies for optimum efficiency in manufacturing procedures. One of the primary methods utilized in precision machining is Computer Numerical Control (CNC) machining, which enables high degrees of precision and repeatability in the manufacturing of bolts.

In enhancement to CNC machining, other precision methods such as grinding, milling, and transforming are typically used to attain the limited tolerances required for fasteners. These techniques permit makers to produce fasteners with smooth surfaces, precise dimensions, and high architectural site here honesty. By utilizing accuracy machining techniques, suppliers can boost the high quality of bolts, minimize product waste, and boost general production efficiency. Additionally, the use of innovative machining procedures assists ensure that bolts meet market criteria and consumer expectations for performance and integrity.

Aspects Influencing Machining Process Performance

Various variables play a considerable function in identifying the performance of machining processes in the manufacturing of bolts. Maximizing these specifications based on the certain requirements of the bolt being produced is vital to attaining affordable and specific machining.

Equipment strength and stability also play an important role in identifying machining process efficiency. An experienced operator can make real-time changes, troubleshoot problems effectively, and ensure that the machining procedure runs smoothly, ultimately influencing the last quality of the bolt.

Quality Assurance Steps in Production

Variables influencing machining process efficiency, such as cutting device option and device security, directly influence the application of top quality control steps in production. Regular maintenance of machining equipment is additionally crucial to copyright high quality control. By sticking to rigid top quality control steps, suppliers can improve consumer fulfillment, construct a track record for reliability, and inevitably accomplish optimal efficiency in their machining procedures.

Verdict

In conclusion, selecting the ideal bolts and utilizing precision machining methods are vital for ideal performance in making processes. Comprehending the kinds and qualities of fasteners, together with aspects affecting machining process efficiency, can cause enhanced efficiency and quality assurance steps. By paying interest to these ins and outs, suppliers can attain higher levels of performance and reliability in their products.

In the world of engineering and production, the option of fasteners and the ins and outs of machining procedures play a crucial role in figuring out the utmost over at this website performance and toughness of an item (Fasteners and Machining). One of the main techniques used in accuracy machining is Computer system Numerical Control (CNC) machining, which allows high levels of precision and repeatability in the manufacturing of fasteners. The usage of innovative machining processes helps make certain that bolts satisfy industry criteria and client expectations for efficiency and integrity

In final thought, selecting the right bolts and using precision machining techniques are crucial for ideal performance in making processes. Understanding the kinds and qualities of bolts, along with aspects influencing machining her response procedure performance, can lead to boosted effectiveness and quality control measures.